Six Sigma

Definition von Six Sigma

Six Sigma ist eine Methode zur Prozessoptimierung und identifiziert regelmäßig die größten Einsparungspotenziale, um diese durch geeignete Teams unter Einsatz von Problemlösungstechniken zu realisieren. Eine große Rolle spielen hierbei statistische Methoden. Geleitet werden die Teams von besonders geschulten Personen – den sogenannten Belts (z.B. Six Sigma Green Belts, Six Sigma Black Belts).

In der Literatur ist auch der Begriff Lean Six Sigma üblich. Dabei handelt es sich nicht um eine schlanke Variante von Six Sigma. Bei Lean Six Sigma wird die Six Sigma Methodik, um Lean Management Tools ergänzt.

Die Anwendung von Six Sigma muss sich nicht auf die Optimierung von Fertigungsprozessen beschränken, sondern kann auf alle Bereiche des Unternehmens angewandt werden, also auch auf Logistik – und administrative Prozesse.

Prozessoptimierung mit der DMAIC Logik

Die systematische Optimierung von Prozessen mit Six Sigma bzw. Lean Six Sigma folgt dem DMAIC Prozess. DMAIC steht für Define – Measure – Analyse – Improve – Control und ist die Problemlösungslogik von Six Sigma. Die DMAIC Logik gibt Anleitung, nach welcher Art und Weise Prozesse zu verbessern sind, um ein vorgegebenes Leistungsniveau (Sigma Niveau) zu erzielen. In den einzelnen Phasen des DMAIC Prozesses werden geeignete Tools des Qualitätsmanagements und der Statistik systematisch angewandt.

Six Sigma Training und Ausbildung

Unsere Six Sigma Trainings sind akkreditierte Ausbildungen, die Sie mit Zertifikat abschließen. Wir unterstützen Ihr Unternehmen nicht nur beim Finden des richtigen Six Sigma Ansatzes, sondern auch bei der erfolgreichen Umsetzung von Praxisprojekten. Durch die Zusammenarbeit mit der akkreditierten Zertifizierungsstelle SystemCert bieten wir Ihnen mit unserer Six Sigma Ausbildungsreihe (Yellow Belt, Green Belt, Black Belt, Master Black Belt) auch internationale Anerkennung. Die Teilnehmer erlernen in der jeweiligen Ausbildung in praxisnahen Übungen die Anwendung der Tools im DMAIC Prozess. Durch die Umsetzung eines Praxisprojektes sind bereits am Ende der Ausbildung nachweisliche, finanzielle Einsparungen garantiert.

Die Rolle des Master Black Belts

Eine Schlüsselrolle bei der erfolgreichen Einführung von Six Sigma spielt der Master Black Belt. Seine Aufgabe besteht darin, die Black und Green Belts bei der richtigen Anwendung der DMAIC Logik und der entsprechenden Tools und Techniken zu unterstützen. Er ist Coach und Mentor für Black und Green Belts, und auch verantwortlich für die unternehmensspezifischen Auswahl der Tools und Techniken. Seine Unterstützung stellt sicher, dass die entsprechenden Einsparungsziele durch Six Sigma realisiert werden.

Six Sigma und Lean Management

Ohne Effektivität (= das richtige Ergebnis im Sinne von Ergebnisqualität) keine Effizienz. Man könnte auch sagen: „Effectiveness first!“. Nur durch den kombinierten Einsatz von Lean und Six Sigma Methoden gelingen die notwendigen nachhaltigen Prozessverbesserungen.

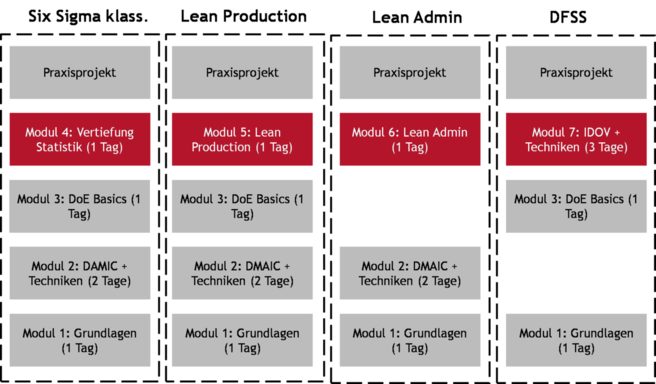

Wir bieten daher unsere Six Sigma Trainings immer in Kombination mit Lean Methoden an, wobei wir je nach Zielgruppen die Schwerpunkte unterschiedlich setzen:

- Six Sigma klassisch mit Fokus auf statistische Qualitätsverbesserung (primär für QM MitarbeiterInnen)

- Lean Production (primär für ProduktionsmitarbeiterInnen)

- Lean Administration (für alle MitarbeiterInnen in Office/Administration)

- DFSS – Design for Six Sigma (für EntwicklerInnen)

Das einzigartige modulare Konzept erlaubt nicht nur einen äußerst effizienten Erwerb der verschiedenen Vertiefungsstufen. Die gleichartigen Module haben auch den Vorteil, dass alle MitarbeiterInnen im Unternehmen dieselbe Sprache sprechen.